Safety managers are tasked with keeping employees free from harm while at work. There are seemingly endless moving pieces involved in accomplishing this goal. One of those moving pieces is a regularly conducted safety walk that promotes safety policies and can even lead to creating new policies.

A safety walk is a specific type of examination that aims to determine how safety policies are performing in real-world conditions. This is judged both by how well employees are following stated policies as well as how effective those policies are at addressing office hazards.

There were 4,572 injury-related workplace deaths in 2019 that were ruled preventable. Every safety manager should routinely conduct safety walks to promote workplace safety and gain a deeper understanding of workers’ day-to-day job responsibilities and the hazards that accompany them. This will help enforce safety policies in real-world conditions and consider creating new policies or refining existing ones.

It’s time to learn how to conduct safety walks to improve workplace safety for everyone at your company. We will then discuss how you can create a safety walk that will effectively promote safety policies throughout the company.

The Importance of a Safety Walk-Around

Safety walks, often called safety walk-arounds, are somewhat informal examinations of the overall safety in the workplace. They should not be confused with safety inspections or audits, which are both formalized processes that are fully documented and quite involved.

The focus of a safety walk is to see the real experiences of workers through a normal workday. Doing so allows safety managers to catch unsafe work practices or situations while they’re happening. This allows managers to train employees on the spot, which helps employees grasp and retain how safety policies impact their responsibilities.

Additionally, safety managers can directly identify problem areas that must be addressed by a new policy or procedure that will correct the issue.

For example, a safety manager might notice that employees are walking too close to equipment due to a restricted pathway. Even though there may be a formalized rule stating that employees should maintain a certain distance from equipment, a restricted pathway may force employees into an unsafe situation. A safety walk can reveal this problem and lead to fixing it.

How to Create an Effective Safety Walk-around Routine

Safety walks must be conducted regularly to be an effective tool to improve workplace safety. Managers must also plan ahead and be armed with the right tools to effectively carry out a safety walk-around.

Begin with a Pre-Inspection

The main reason behind a pre-inspection is for the safety manager to familiarize themselves with the workplace when it’s operational. A pre-inspection will follow the same walking route as the actual safety walk, but the purpose is to understand the workplace rather than interact with employees.

Pre-inspections won’t need to be carried out before every safety walk. They’re primarily required when a safety walk program is being created or when a new manager starts conducting them.

Focus on Addressing Real-World Activities when Planning

Safety walks don’t require a significant amount of planning, but managers still need to plan ahead. In addition to the pre-inspection, reviewing previous safety inspections and audits will help the manager understand specific areas that need attention.

Planning a safety walk is more about being aware of problem areas and common causes of injuries within the workplace. Types of injuries that occur more frequently should receive more attention.

Managers don’t need to plan an exact agenda to follow with some exceptions for large facilities. Otherwise, the focus is entirely on interacting with employees while they perform real-world activities to enforce safety policies. The secondary focus is to gain a deeper understanding of each workers’ responsibilities.

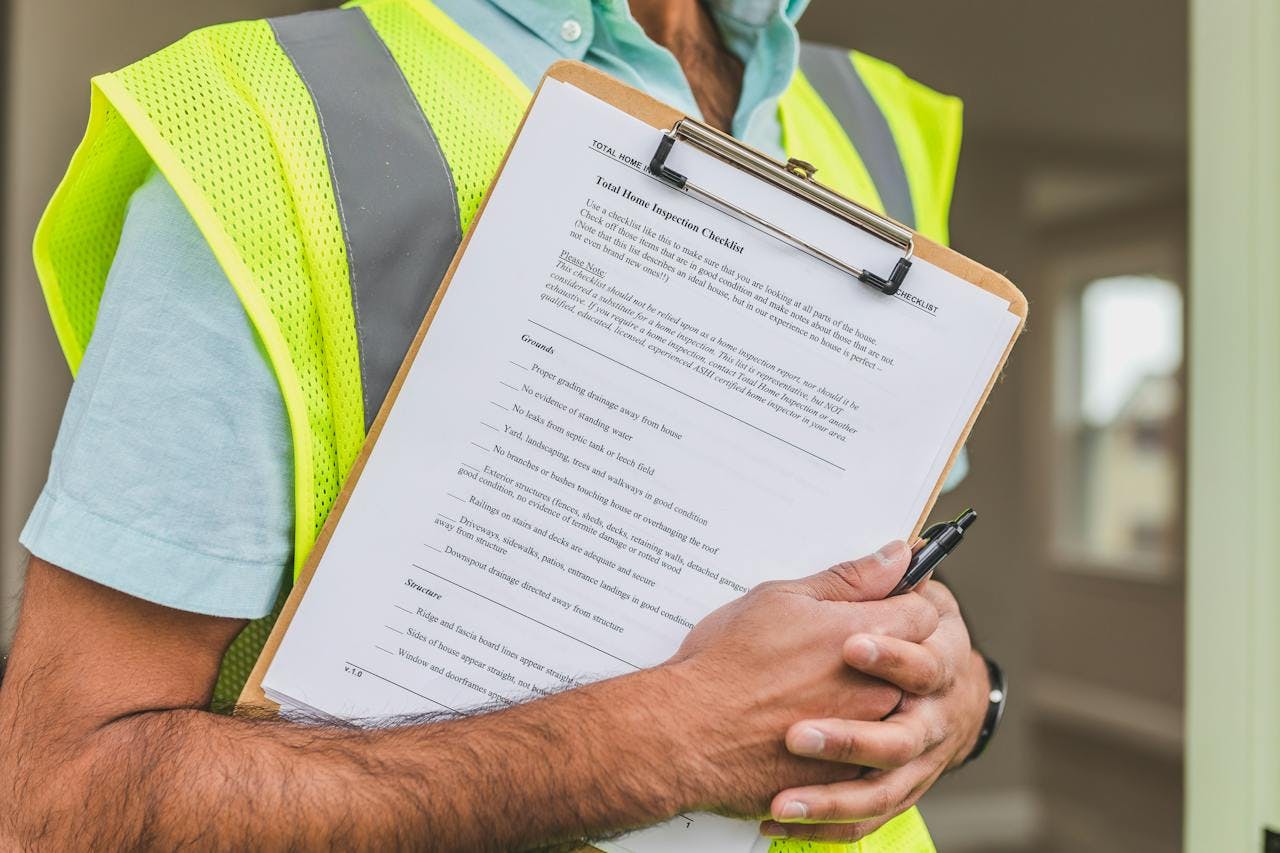

Gather Meaningful Data by Having the Right Tools

Inspections and audits are focused on data gathering while safety walks are not. However, safety managers should still be armed to collect any data that may seem relevant while they conduct the walk.

Safety managers should have a workplace safety management tool with mobile inspection software that allows them to document any issue they encounter. Managers can easily take and store pictures while taking notes about any concerning issues.

Conduct Effective Safety Walks with Planning and Consistency

It is vitally important that safety walks are conducted regularly. Some businesses conduct them daily, while others have opted for weekly or monthly walks. You’ll need to determine what regularity makes sense for your company.

Consistency is important so that safety managers continually catch issues occurring in real-world situations, which are not going to all happen on the first safety walk. Schedule safety walks into your schedule to reap all of the benefits of this practice.

Planning ahead helps safety managers bring the right tools and be aware of problems areas before safety walks. They must be able to fully document any problems or concerns that may arise in order to fully address them after the safety walk.

Ensure that your company has a mobile inspection app that empowers managers to document issues for future analysis. Book a demo today to see how monitorQA can make a difference.

last modified:09.17.24

Recent Posts

OSHA Ladder Safety 101: How to Meet OSHA Standards and Keep Your Workers Safe

Car Wash Safety: Regulations & Best Practices You Need to Know

Fall Hazards At Work: How To Keep Your Employees Safe

The High Price of Neglect: OSHA Violations and Penalties

Expert Advice on Preventing Workplace Electrical Hazards

Slips, Trips and Falls in the Workplace: Best Practices

HSEQ Audit: The Complete Guide

Keeping Up With Compliance Trends 2024

Improve Safety: Inspection Management Software Benefits

Promoting Safe and Productive Working Environments: Occupational Health & Safety Tips to Consider