Understanding the safety pyramid is helpful for anyone looking to reduce the number of injuries and fatalities in the workplace. The concept behind the safety pyramid was created in the 1930s and has been further developed since its inception.

The principle behind the safety pyramid is that for every major injury or fatality, there are a far greater number of minor injuries and unreported accidents. The exact numbers have been studied and debated ever since the inception of the safety pyramid, but most professionals are in agreement with the overall principle.

Today, we’re going to explore more about the safety pyramid, briefly discuss its history, give an overview of prominent criticisms, and explore how your business can use the safety pyramid to create a safer work environment.

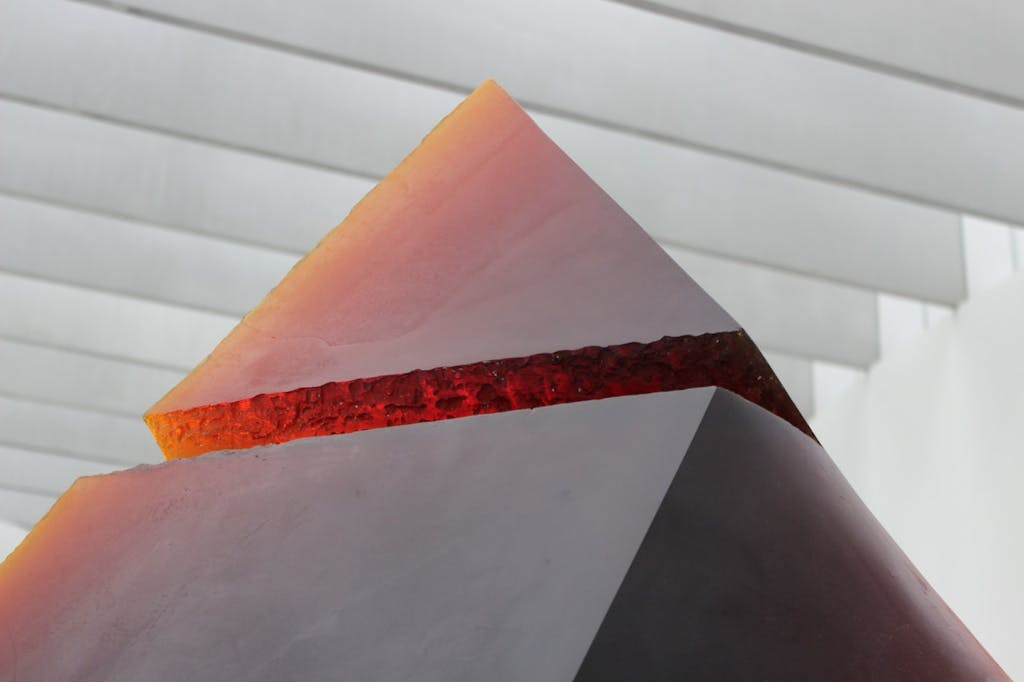

What is the safety pyramid?

The concept of the safety pyramid was first created in 1931 by an employee of an insurance company. Herbert Heinrich studied approximately 75,000 accidents and published a theory for reducing industrial accidents. The theory can be summarized with a pictorial pyramid that showcases that by preventing 300 incidents, major injuries can be avoided or eliminated. The numbers in Heinrich’s pyramid are:

- 29 accidents with minor injuries for every 300 accidents with no injuries

- 1 accident with major injuries per 29 accidents with minor injuries

This helped shift the focus on injury prevention to preventing all accidents, instead of honing in on only the severe accidents.

In 1966, Frank E. Bird used the same hypothesis and analyzed over 1.7 million accident reports from over 300 companies. His pyramid adds more steps and has the following figures:

- There are 30 minor accidents for every 600 near misses

- There are 10 serious accidents for every 30 minor accidents

- There is 1 death for every 10 serious accidents

The addition of fatalities to the safety pyramid further exemplified the entire theory behind it. There have been further incarnations of the safety pyramid, each of them supporting the same principle. However, the safety pyramid is not without its critics.

Criticisms of the safety pyramid

The safety pyramid is not an infallible rule. There has been plenty of criticism of the safety pyramid since its creation. Some of the most common critiques are:

- It focuses the problem on behavior: The most common critique of the safety pyramid is that it puts all of the responsibility for accidents on employee behavior. In reality, management practices, level of training, and company policies all play a role in how many accidents occur.

- The ratios are not always correct: Many safety experts are quick to point out that the ratios reported by Heinrich’s and Bird’s pyramids are not universally true. Different industries will experience a different relationship between the pyramid’s tiers.

- The relationship between tiers is not applicable across all hazard classes: One hazard class may directly reduce major injuries, but this isn’t true for all classes of hazardous materials.

It’s important to note that while each of the criticisms is valid, they do not contradict the overall purpose of the safety pyramid. How can companies incorporate these purposes into their workflow?

Incorporating the safety pyramid’s principles

Despite its criticisms and flaws, organizations of all sizes can learn from the safety pyramid. The guiding principle beyond the pyramid is that minor accidents lead to major accidents. How can your company learn from this?

One of the most direct ways to put this principle to work is to emphasize the importance of following safety guidelines at all times. This can be done by utilizing digital checklists that allow employees to carefully follow protocol and track any issues that might arise. Management can also use digital checklists to monitor employee’s adherence to safety policies.

There’s not a dire need to worry about the exact values and ratios described in the pyramid. However, near-misses and minor accidents should receive a thorough risk analysis to prevent more serious injuries in the future.

Increase overall safety with digital inspections

The main lesson to learn from the safety pyramid is that there is a statistical relationship between near-misses, minor injuries, major injuries, and fatalities. Companies should treat each occurrence of every category as a warning that more severe injuries are on the way.

By properly monitoring the adherence to safety protocols, companies can greatly reduce workplace accidents.

Are you looking to streamline workplace health and safety at your company? monitorQA is a digital inspection tool that simplifies quality assurance and control through intuitive functionality, collaboration, and deep insights. Get in touch with our team today to start your free trial.